Crane Onvalla

Cranes can be categorized by structure type and function, depending on the application, space, and individual customer needs. Onvalla Co., Ltd. has a team of experienced engineers who can design cranes to suit each customer’s needs.

Onvalla Co., Ltd. utilizes the DIN standard for the design of the center beam, a standard from Germany. During the center beam production process, QA and QC are performed at every stage, in accordance with the company’s standards. Onvalla Co., Ltd. holds ISO 9001/2015 and ISO 45001/2018 certifications. Our team of experts designs cranes to suit each customer’s application. The structure is calculated with user safety in mind, ensuring maximum satisfaction and confidence in crane operation.

Single girder overhead crane

This type of crane is widely used in industrial plants, both large and small, which is suitable for applications with not much lifting weight. The recommended lifting weight is 0.5 – 20 tons, the working width is from 4 – 40 meters, the lifting height depends on the needs of each customer. For the lifting direction control system, you can choose either the Double Speed system which has 2 movement rhythms: slow and fast movement in the same direction, or the Inverter system, which is a system that uses electricity to help control the direction, making the movement smooth. The choice of control system depends on the customer’s needs.

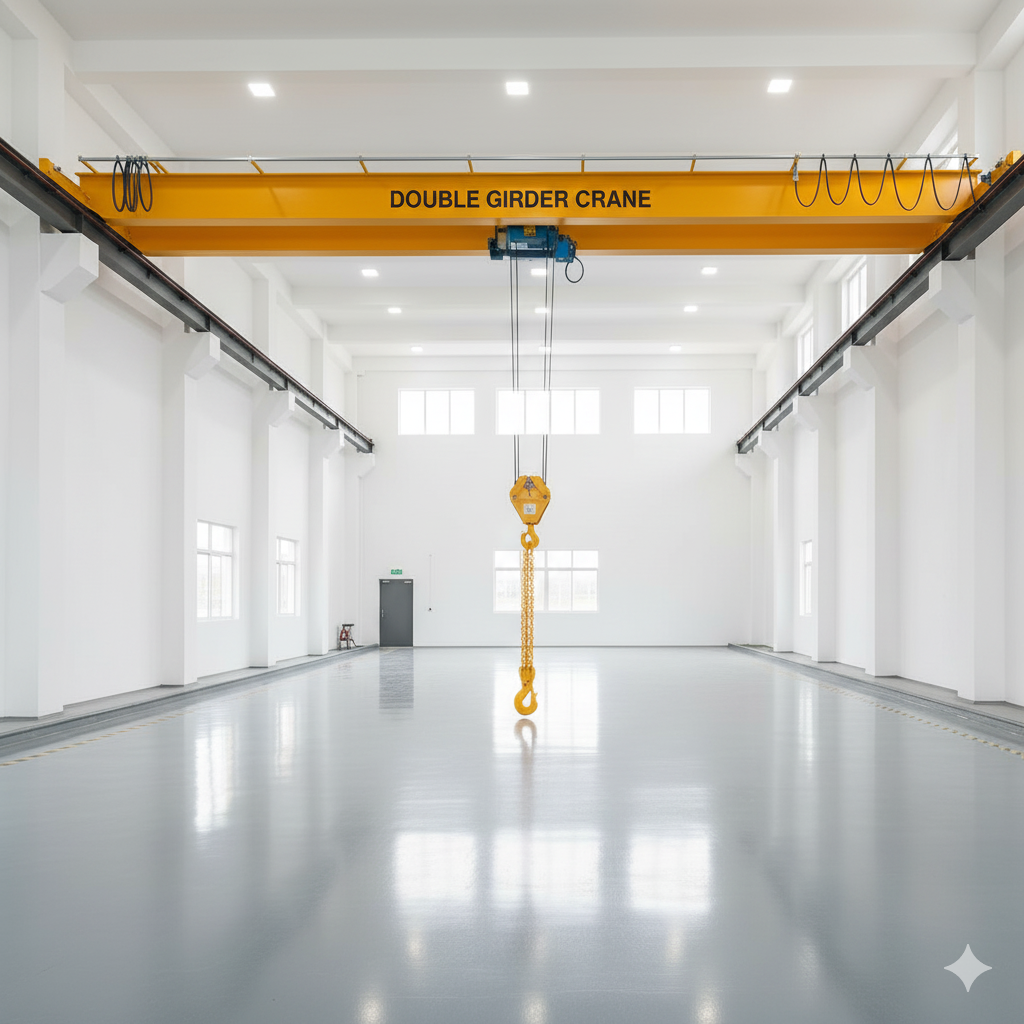

Double girder overhead crane

This type of crane is mostly used in heavy industries that require lifting heavy weights, such as steel roll storage warehouses, automotive parts assembly plants, power plants, etc. Due to the high lifting weight, it is necessary to increase the weight-bearing beam to a double beam type. Suitable lifting weights range from 2 – 500 tons, working widths from 10 – 50 meters, and working heights depend on the limitations of the work site and the needs of each customer. Onvalla Company Limited has a team of experts in designing cranes that are suitable for use with each customer. The structure of use is calculated with the primary consideration of user safety.

Overhead crane suspended under rails

The crane will run below the crane runway, with the long-running wheel beams hanging from the crane runway. They can be designed and built in either single-girder or double-girder configurations. This type of crane is suitable for industrial buildings that require full-area use and those that require the widest possible area, such as large aircraft maintenance hangars.

Double girder gantry crane

This type of crane is suitable for outdoor and indoor installation under the factory roof. For factories that do not have a column structure prepared to support an overhead crane, it is necessary to install a 2-legged field crane placed on the factory floor. It has the same characteristics as a single-girder overhead crane that is suitable for industries that lift light weights. Lifting weights from 1-20 tons will have an appropriate working width of 6-40 meters. Onvalla Company Limited has a team of experts in designing and calculating the crane structure to be suitable for use and taking into account the safety of the users as a priority.

Single girder, single-legged gantry crane

It is suitable for use in factory areas by installing the upper running track on the pillars on the side of the factory building or installing it indoors and installing the running track on the floor below the factory building. Users can also design the crane in the factory to be 2 levels. Generally, it has a working width of 6-40 meters and a lifting weight of 1-20 tons.

Cantilever crane with swivel arm

It is suitable for lifting objects or products in specific areas. The radius of the arm that rotates is 20 meters and the lifting weight is from 1 – 20 tons. However, the limitation is the degree of rotation of the arm, depending on the wall of the customer’s work site.

Wall mounted crane with swivel arm

It is suitable for lifting objects or things in specific areas around the radius of the crane’s rotating arm, similar to a column-mounted crane with a rotating arm. However, the difference is that it uses the factory building’s pillars as a structural support for the arm to rotate. However, the limitation is the degree of arm rotation, which depends on the wall of the customer’s work site.

Wall-mounted crane, lifting arm

It is suitable for lifting objects or products along the length of the side walls of the factory building. The wall-mounted crane has a set of 3 legs, 6 wheels, running on 2 levels of rails. The entire set of crane legs is installed on the 2-level running rails, attached to the pillars on the side of the factory wall, and the crane beam set extends out independently to lift objects or products. The use of lifting objects along the side of the building is the same as the single-legged field crane, but it is more convenient.

Single girder crane

The hoist is installed and moves along a single track that is installed according to the structural conditions of the manufacturing process. The track is a single track that can be designed to be a straight line or curved according to the conditions of the work area. The hoist can move forward, backward or run into a curve. It is used for lifting weights of approximately 0.5 tons to 20 tons. With the following design, it can work in only four directions: forward – backward – moving up and down vertically.

Onvalla Company Limited

Onvalla Co., Ltd. has over 20 years of experience. Our team of expert engineers and staff are happy to provide consultations to all customers, including crane selection, installation, operation, and maintenance. This ensures that customers receive high-quality, safe, and appropriate hoists and cranes. Our cranes are used in a variety of industries, including the automotive, auto parts, steel, oil and petrochemical, power plants, prestressed concrete, cement, and many more.

For customized designs, Onvalla Co., Ltd. has a team of experts to provide consultation and recommendations for maximum benefit to customers.