Warehouse System

Warehouse System

ONVALLA offers warehouse products with design, installation and warranty services. Systems are managed to meet ISO 9001 quality standards to meet consumer needs and fit every type of customer. The Company manages material handling for warehouse system and all types of related equipment with cooperation from experts of leading manufacturers and modern manufacturing technology accepted by Asia, Europe.

A good warehouse system facilitates management, receipt and storage to send products to recipients to facilitate sales activities with accuracy and speed, which is the main goal of current business operations, quality control in storing, picking products and reducing prevention of operating losses in order to minimize operating costs and fully benefit from current space or limited space.

ONVALLA is accepted in every circle as a leader in the area of material handling systems with experience in every market of the business such as manufacturing industries, product storage and distribution warehouses, transportation-logistics, cold rooms for food storage, construction and activities in every area related to the government and state enterprises. We have been in this business for over 30 years. Rest assured that in our service standards can take care of customers’ every need and meet customer demand for warehouse solution products.

Dorner Conveyors

Dorner’s wide variety of industrial, precision and sanitary conveyance solutions are designed to optimize your efficiency and productivity

FlexMove

● FlexMove Conveyors

![]()

![]()

![]()

![]()

![]()

FlexMove Conveyors If you are looking for a high quality flexible conveyor system, the FlexMove offers superior efficiency and productivity for virtually any application. This model is one of the best flex conveyor systems on the market.

● FlexMove Stainless Conveyors

FlexMove Stainless Series Conveyor

- Stainless Steel Construction is ideal for corrosion resistant applications or packaging lines

- Provides capability for vertical incline with minimal floor space

- Features modular framing for future add-on capability and production line changes

- FlexMove Solutions eliminates unnecessary cutting, inventory and waste

● FlexMove Alpine Conveyors

FlexMove Alpine Conveyors The Alpine Conveyor is a compact spiral configuration commonly used as an accumulation or elevating buffer zone between machines or as a process step for cooling or drying. It can also be used for line balancing or product changeover purposes.

● FlexMove Helix Conveyors

FlexMove Helix Conveyors

Compact spiral & helical curve, flexible chain conveyors for complete flexibility!

Unique, flexible design provides greater flexibility in layout

● FlexMove Twist Conveyors

FlexMove Twist Conveyors

Rotate products easily and efficiently with flexible chain twist conveyors.

- Positively control the product during rotation

- Provides product rotation for access to multiple sides of packages

- No change over –can handle multiple package sizes at the same time

● FlexMove Wedge Conveyors

FlexMove Wedge Conveyors Our Wedge Conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors aligned vertically or horizontally and are moved swiftly but securely.

● FlexMove Pallet System Conveyors

FlexMove Pallet System Conveyors Our highly advanced FlexMove Pallet Systems are flexible conveyors with pallets for product routing and control.

1100 Series

The 1100 Series conveyor platform is the industry’s smallest conveyor with a compact design featuring a 3/4″ frame height. This low profile enables the conveyor to fit into the tightest of spaces, freeing up valuable machine or worker space.

2200 Series

2200 Series low profile, high performance fabric and modular belt conveyors feature a high speed nose bar transfer option, a durable single piece frame design, universal T-slots, and a wide range of belting and guiding options.

3200 Series

Sanitary, Stainless Steel Conveyors

Dorner’s AquaGard & AquaPruf sanitary conveyors are engineered to promote hygienic design while meeting the sanitary standards of the Baking Industry Sanitary Standards Committee (BISSC), National Sanitation Foundation (NSF), 3A, USDA and other FDA regulations.

AquaGard

AquaPruf

HELI Forklift

HELI has entered a rapid development period, in 2006, the world’s top ten forklift industry. Today we put forward into the world’s first group of forklift industry, to enter the world’s top five goals, is the history of our glorious heritage, but also the pace of HELI people will never stop!

◦ Lithium Battery Forklift Series

◦ Lithium Battery Reach Truck Series

G2 Series 1.6-2t lithium battery

reach truck (sit-down type)

G2 Series 1.5-1.8t lithium battery

reach truck (stand-on type)

◦ Engine Forklift Series

◦ Electric Stacker & Pallet Truck Series

Quotation Request

RACKING SYSTEM

RACKING SYSTEM Different types of racking are widely used. There is no structural complexity, makes it easy to place products in the warehouse & comfortable. It’s the most appropriate and meets your needs. Available in small to large racking, it provides storage efficiency, providing the best value for investment.

SELECTIVE RACK

Selective Racking, also known as Pallet Racking. This system suits to store various types of goods on pallets, making it easy to move products, easy to store, and able to control stock according to your needs. It receives the weight of heavy products very well, stable and strong, using only 35% of the storage space. The beams of the shelf can be leveled according to the size of the goods.

DRIVE-IN RACK

Drive-In Racking System It has the appearance of a tunnel, suitable for storing the same goods. This system saves lanes, so has 35% more storage space compared to selective racking systems.

We can design a drive-in racking system to suit the product structure and warehouse space, effectively capable. The level can be adjusted to suit the characteristics of the goods that need to be stored. It is possible to choose from pre-galvanized pillar structures, strong and durable in all weather.

DOUBLE DEEP RACK

Double Deep Racking System is the same type of product storage as the Selective Racking System. It will be different by changing single-row racks aligned to the wall are double rows, while double-row racks increase storage space by about 20-30 percent more than selective racking systems.

Double Deep Racking System is ideal for storing identical products. It can load of 500-3,000 kg per level, it can store goods up to a height of 12 meters, it must work with telescopic forklift or reach truck.

PUSH BACK RACK

PUSH BACK RACK is a cargo rack designed for use by forklifts. Like Dive -In, just push the pallets placed on the carriages, causing the flow along the rails ( the appearance of the rails, which has a low-back high front ) in each rail can be stored up to 6 pallets deep, and the final pallet is placed on the beam to provide enough friction to prevent the 6 pallets from flowing backwards.

VNA RACK

VNA or Very Narrow Aisle Racking System is a storage system similar to selective racking and double deck racking system, but it can store more products in the same space as it uses only 1.5-2 meters of lane.

PALLET FLOW STORAGE RACK

Pallet Flow Racking Systems The characteristic of this type of rack is to combine racks with rollers and use gravity to drive goods from the loading side to the unloading side. Whether it’s Pallet Shuttle Racking Systems or Radio Shuttle Racking Systems, the overall functionality is the same. Same behavior Focus on deep storage of goods. First-In, First-Out (FIFO) functionality can be categorized at each tier.

CARTON FLOW RACK

Light FIFO Carton Flow RACKING SYSTEM A sliding cargo storage system. It is usually used for packaging management and selection for operations in warehouses, distribution centers and manufacturing facilities. Designed to increase operational efficiency resulting in significant costs, raw materials and high-quality equipment

CANTILEVER RACK

CANTILEVER RACK Refers to a layer that is designed to look appropriate for the placement of long objects, pipe type, paste, wood or steel jewelry. The gluten method is said to save space, which is convenient to store because there are no poles and can be fitted with a roof for outdoor use. Industries that use cantilever racking Plastic pipe

SHUTTLE RACK

Shuttle Rack System is a high-density storage system. It can solve warehouse problems effectively. It is a new alternative to the storage model that can make more cost-effective use of space inside the warehouse.

MOBILE RACK

Mobile Racking It is a mobile storage rack. This makes it possible to make the most of the warehouse space and have convenient and safe access to the goods.

Quotation Request

Warehouse Accessories

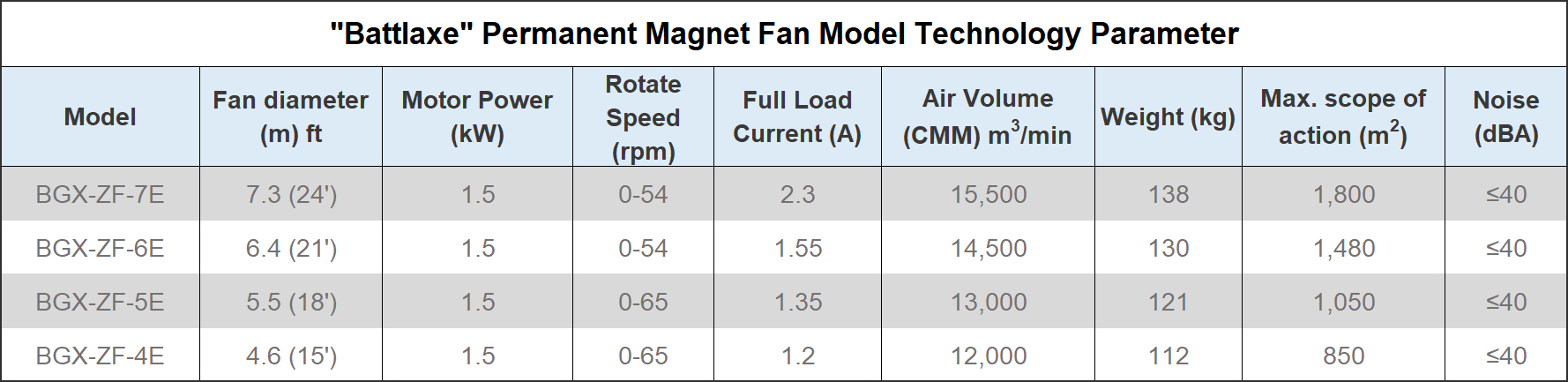

◦ HVLS Fan (High Volume Low Speed Fan)

ONVALLA-BIG FAN Giant fan For factories, warehouses, skytrain stations, airports, gymnasiums, schools, hotels, auditoriums, supermarkets, religious establishments, churches Use technology. Permanent magnet motor (Permanent magnet Synchronous Motor-PMSM)

- Helps circulate air for enclosed and open spaces, improving pollution.

- Reduce the temperature by 5-8 degrees Celsius cells.

- Energy savings compared to installing small fans

- It covers a lot of space.

- Dehumidification Anti-corrosion

- Designed with a total of 6 blades for all sizes, the impellers are made of alloy and aluminum. Use the same grade of material used in airlines from the United States. Aa6063T6511

- The 1.5 kW IP65 motor is 91% high efficiency, small in size but with high torque, maintenance-free of all parts. General gear, low operating motor temperature(about 60 degrees)

- VFD -Variable Frequency Dive by Inverter DANFOSS

- It has electrical protection and overloading.

- Fan speed can be adjusted from 0-54/0-65 rpm (according to propeller size).

- Use grips in high-strength installations. Use a 12.9 standard DIN933 trade nut and DIN125A unscrewing solution.

- Physical protection, anti-fall, high tensile strength, impeller clamp made of 40 Gr metal castings.

◦ Shelving Series

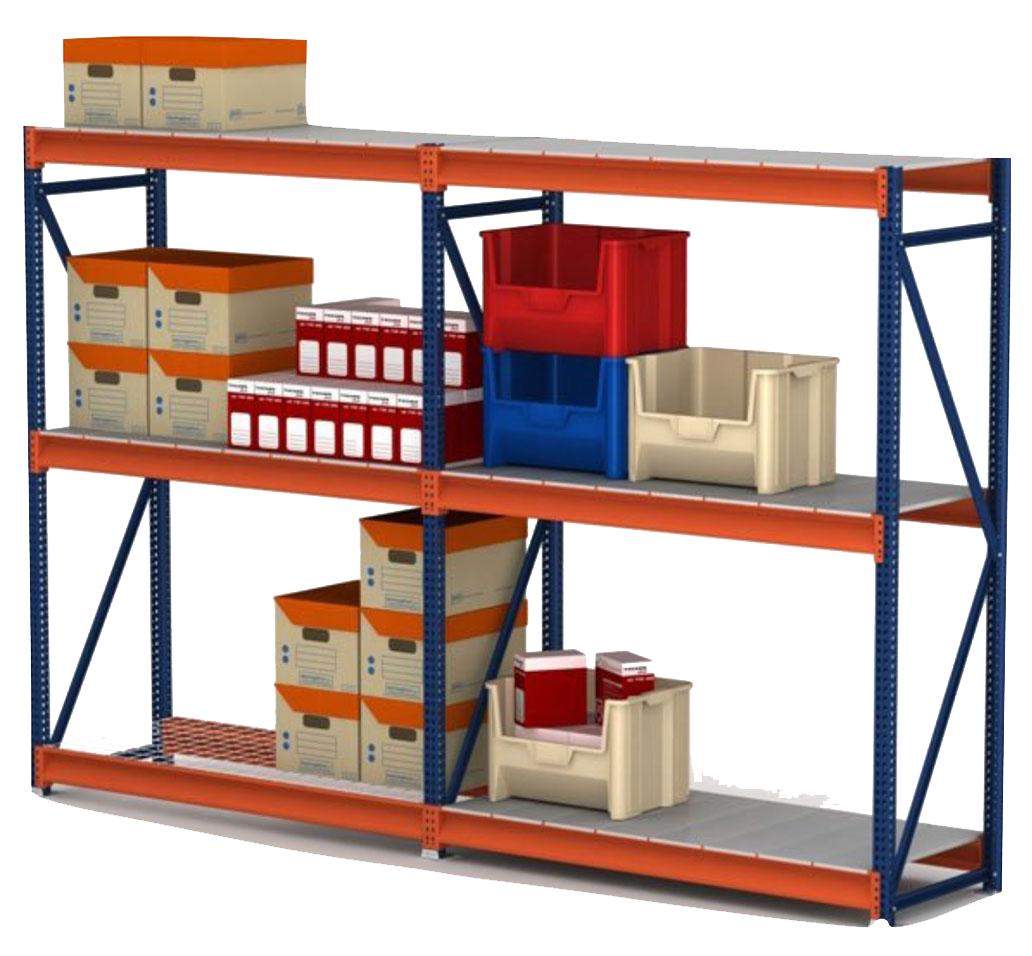

LONG SPAN SHELVING

The selective rack is adapted from the Selective Rack for placing goods that do not rely on pallets to store only plywood or steel sheets on the main beams and reinforced with deep beams, capable of weighing from 200-300 kg.

INDUSTRIAL RACK SHELVING

Small and medium shelf with economical prices. Designed to suit various product styles.

BOLTLESS REVET SHELVING

Boltless Shelving provides easy access to stored items from all sides. Commonly used storage racks, fixing pins, load racks, ≦ 180 kg per layer belong to light shelves.

ANGLE STEEL SHELVING

Angle steel shelving is a robust, versatile and economical shelving system, widely used in automotive archives, factories, warehouses, retail, wholesale and commercial. It is a versatile corner steel, designed for the connection of shelves and other metal structures

SUPER MARKET SHELVING

Super Market shelf It’s a shelf. Modern stores such as convenience stores, hardware stores, retail stores, auto parts stores are designed to suit the type of product to be placed or displayed. It can withstand loads very well, is easy to disassemble, installs and increases the ability to store a wide range of equipment with a wide range of accessories. To hang the goods, steel layer plates. Product baskets, punching back panels or grill panels with hooks can be adjusted to suit the customer’s product placement as needed.

MOBILE SHELVING

Mobile Racking It is a mobile storage rack. This storage system is driven by wheels that are driven by electric motors and plc control system, making it highly safe.

◦ Racking Accessories

WIRE MESH DECKING

FLARED CHANNEL

INVERTED FLARED

INVERTED CHANNEL

UPTURNED WATERFALL STYLE

RACK GUARD

◦ Logistic Container

PLASTIC PALLET/STEEL PALLET/ALUMINUM PALLET

WIRE CONTAINER

STEEL PALLET BOX

PLASTIC CONTAINER

◦ Handling Equipment

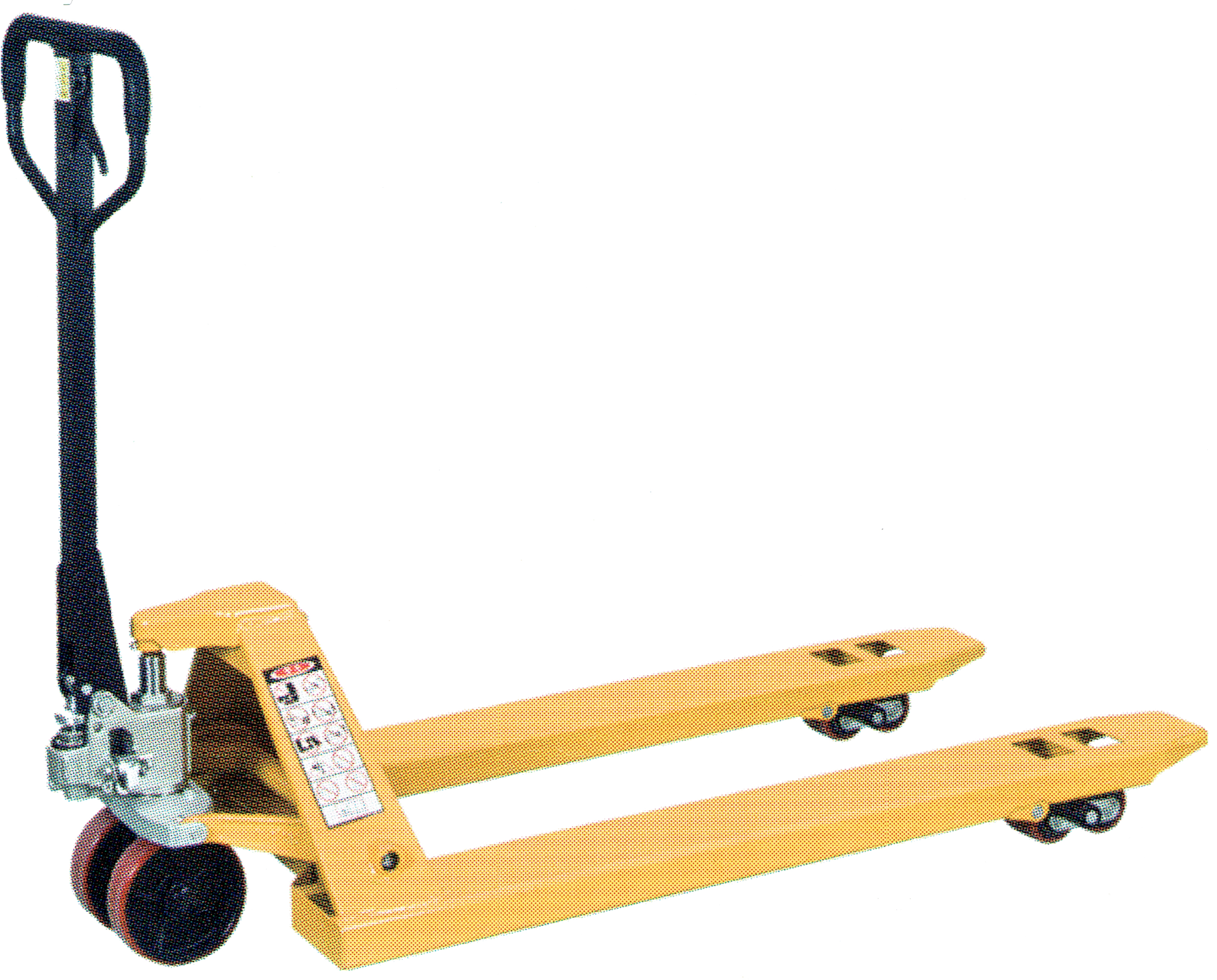

PALLET TRUCK

PALLET STACKER

PLATFORM TROLLEY/TRUCK

SELF-PROPELLED ELECTRIC / SCISSOR LIFT

LOGISTIC TROLLEY

HAND TRUCK